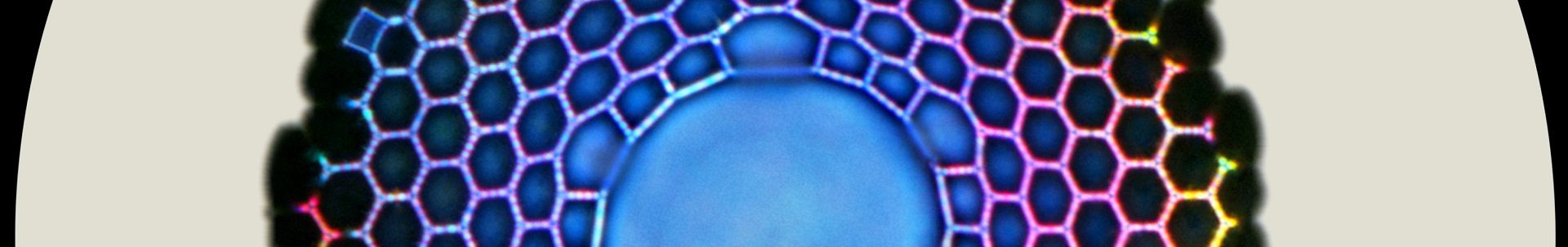

Presented at Frontiers In Optics this week is an analytical model to predict the fabrication parameters and fibre geometry for hollow core anti-resonant tubular fibres. Such a model can identify the parameters for the draw to improve efficiency, and can check the feasibility of given geometry. The model also helped identify dynamics that occur within the furnace otherwise hidden to the fabricator.

Virtual draw model for tubular anti-resonant hollow core fibres

Gregory T. Jasion, John R. Hayes, Natalie V. Wheeler, Yong Chen, Thomas D. Bradley, Seyed Reza Sandoghchi, Marco Petrovich, David J. Richardson, and Francesco Poletti